Qué es la ratio de extracción de un suplemento

En el mundo de los productos de hongos puros es habitual encontrar en las etiquetas indicaciones de concentración y ratio de concentración como 4:1, 15:1 y otras.

Sin embargo, a pesar de su uso generalizado, pocos consumidores comprenden realmente la importancia de este indicador.

Como laboratorio experto en este campo, hemos elaborado este artículo para ayudarle a comprenderlo, pero este vídeo también es un magnífico resumen para empezar.

Publicado el 26/07/2024

Autor: EQUIPO EDITORIAL HIFAS

Por favor acepte el consentimiento de cookies

COMPRENDER LA RATIO DE CONCENTRACIÓN O EXTRACCIÓN

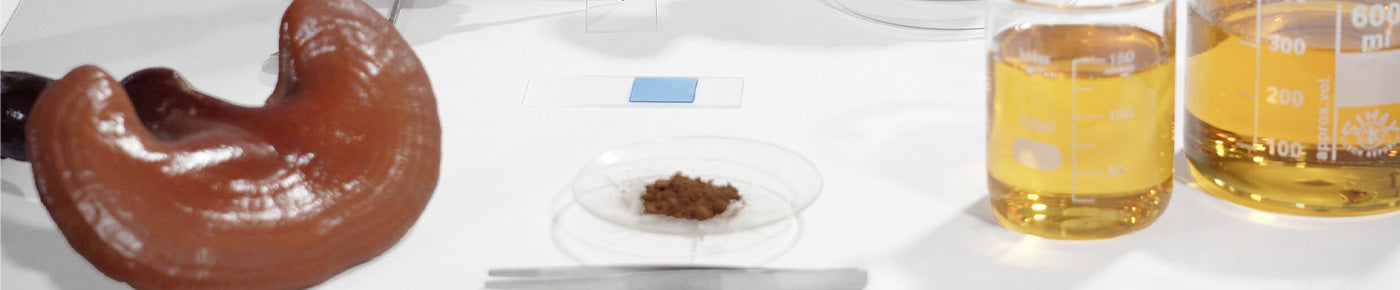

En el envase de muchos complementos alimenticios a base de hongos, la ratio de extracción, o ratio de concentración, establece un vínculo entre la cantidad de materia prima y la cantidad de material final. Por ejemplo, una proporción de 15:1 significa que se necesitaron 15 gramos de setas para producir 1 gramo de extracto.

Los laboratorios suelen utilizar los ratios de concentración como argumento para promocionar sus productos. A primera vista, un índice de extracción elevado implica un extracto más concentrado, potencialmente más rico en compuestos beneficiosos que un producto con un índice inferior.

Estas ratios también se utilizan para justificar el precio ante el consumidor, porque un producto con un ratio más alto implica lógicamente una mayor cantidad de moléculas bioactivas, ¿no? No del todo. Lo explicamos a continuación.

LOS LÍMITES DE LA TASA DE EXTRACCIÓN

La mayoría de los consumidores piensan que una mayor proporción de concentración significa un producto más potente, pero en realidad esto depende de varios factores:

1. ¿DE QUÉ PROPORCIÓN ESTAMOS HABLANDO?

Es fundamental saber de qué proporción de concentración estamos hablando. Para algunos, la proporción corresponde a la cantidad de setas frescas comparada con la cantidad de polvo, mientras que para otros, el punto de partida es la cantidad de polvo para hacer un extracto. En el primer caso, la masa de seta fresca incluye el agua contenida de forma natural en la seta, mientras que en el segundo, se excluye.

Sin embargo, algunas setas contienen una cantidad significativa de agua. Por ejemplo, el simple secado puede eliminar hasta el 90% del agua de un hongo como el Agaricus blazei, dando una proporción de 10:1, pero sin ninguna extracción real. Sin extracción, los metabolitos secundarios quedan atrapados en la matriz quitinosa del hongo, lo que hace que estas biomoléculas activas no estén biodisponibles.

2. ¿DE QUÉ TIPO DE EXTRACCIÓN ESTAMOS HABLANDO?

Para obtener un extracto completo de una seta, es necesario realizar una extracción. Esta extracción puede llevarse a cabo de dos maneras: de forma simple, utilizando agua o alcohol como disolvente, o de forma doble, utilizando ambos. La utilización de uno u otro método de extracción depende del hongo en cuestión y de la polaridad de las biomoléculas activas presentes en él.

En el ámbito de los hongos puros, a menudo se recomienda optar por una extracción doble, que combine agua y alcohol (= extracción hidroalcohólica), en lugar de una extracción única. Esta preferencia se explica por el hecho de que una extracción con agua sólo permite recuperar moléculas hidrófilas (= amantes del agua), como los betaglucanos, mientras que una extracción con alcohol permite recuperar otras moléculas de interés, como los triterpenos. Además, los disolventes utilizados se eliminan durante el proceso, lo que garantiza la seguridad del producto final.

Aunque una extracción doble puede proporcionar una mayor cantidad de polvo, su proporción de concentración puede ser a veces menor que con una extracción de agua sola. Sin embargo, esto no significa que la extracción con agua sea más potente. Al contrario, una extracción doble puede ser más eficaz porque permite extraer una gama más amplia de componentes.

En Hifas da Terra, nuestra experiencia en hongos puros y técnicas de extracción se remonta a más de 25 años, junto con todos nuestros análisis posteriores. Estos nos permiten determinar si es preferible una extracción hidroalcohólica o acuosa, en función de los compuestos (hidrófilos o no) que queramos concentrar en cada seta concreta.

UNA SOLUCIÓN: LA COMPOSICIÓN DE MOLÉCULAS BIOACTIVAS

En resumen, basarse únicamente en un simple indicador de proporción no basta para evaluar la calidad real de un complemento alimenticio a base de hongos puros.

Para obtener información significativa, es esencial disponer de un desglose detallado de los bioactivos en la etiqueta. De acuerdo con nuestra guía para elegir el mejor suplemento a base de hongos puros, es fundamental analizar detenidamente el etiquetado. Lo que realmente cuenta es la cantidad de moléculas bioactivas mencionadas en la etiqueta, así como los compuestos bioactivos específicos del hongo adquirido, como la cordicepina (Cordyceps), el inotodiol y la betulina (Chaga), el grifolan (Maitake), entre otros. Para estar seguros, es necesario realizar pruebas analíticas de los compuestos bioactivos y mediciones de pureza.

También debe tenerse cuidado al cuantificar la concentración o el porcentaje de ingredientes activos no específicos, como los polisacáridos. Es preferible especificar los betaglucanos fúngicos (1,3/1,6), científicamente reconocidos por su función inmunomoduladora.

También protege contra el riesgo de comprar una falsificación, dado que los estudios de los mercados europeo y estadounidense han revelado graves deficiencias en materia de trazabilidad.

En otras palabras, sin un análisis sólido de las moléculas bioactivas específicas y su indicación en la etiqueta, los consumidores no tienen ninguna garantía de que estén adquiriendo un producto a base de setas, y mucho menos un producto a base de hongos

HIFAS DA TERRA: UNA EMPRESA EXPERTA EN OBTENER EXTRACTOS A PARTIR DE HONGOS PUROS

Como empresa biotecnológica experta con 25 años de experiencia, nuestro compromiso es diseñar un proceso de fabricación específico para cada seta, teniendo en cuenta sus características individuales. Cada seta tiene sus propias moléculas bioactivas, por lo que es necesario desarrollar procesos únicos para aprovecharlas al máximo.

Esto es precisamente lo que nos esforzamos por hacer a través de nuestros análisis cuantitativos en profundidad de nuestras cepas fúngicas. Estos análisis nos permiten comprender mejor los perfiles bioactivos de cada hongo y diseñar enfoques de extracción y producción adaptados a sus características específicas.

Para garantizar la calidad y consistencia de nuestros productos, aplicamos rigurosamente nuestro sistema de gestión de calidad, conocido como “Sistema de Calidad Hifas”. Este sistema nos permite controlar todas las fases del proceso de producción, desde el cultivo de las setas hasta la formulación de los productos finales, para garantizar que nuestros clientes reciban siempre productos de la máxima calidad y eficacia.